As more and more shops adopt multiaxis practices, we have invested more into improving our Multiaxis product. Explore these three new Mastercam 2023 Multiaxis tools, created with users like you in mind.

Unified Multiaxis Toolpath

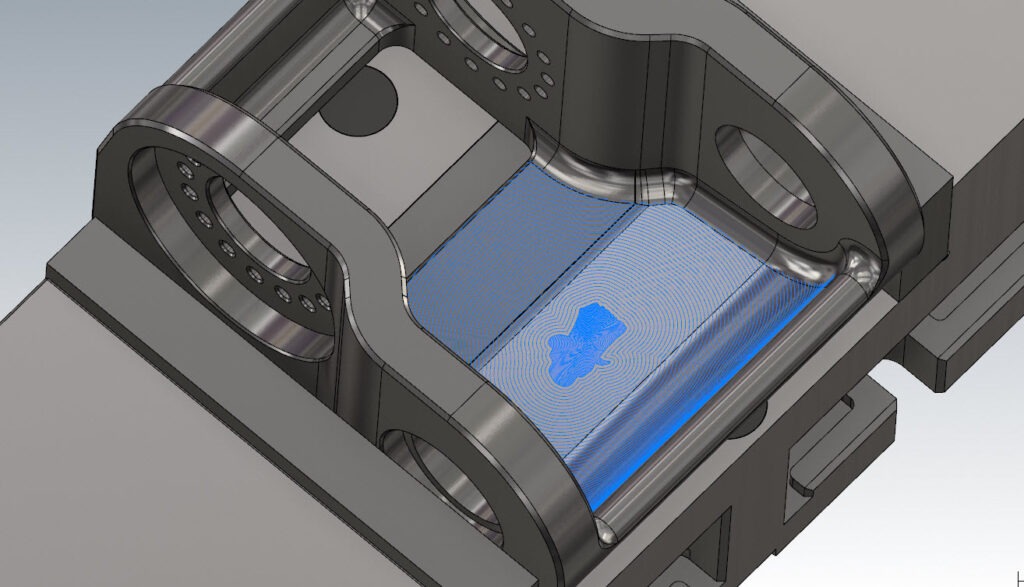

Boosting efficiency begins the moment a part file is opened in Mastercam. Instead of requiring a user to spend extra time and mouse miles searching through multiaxis options, all of the multiaxis functions are available in the Unified Multiaxis Toolpath. Once a user inputs the appropriate curves, they can access Morph, Parallel, Along Curve, and Project Curve all from one consolidated location.

For example, in the Mastercam Manufacturing Lab, Applications Engineers use Unified to rapidly create and analyze cut types on the Witch Doctor BattleBot parts, where visual flair is just as much of a toolpath requirement as surface finish. Being able to experiment with these pattern options without the overhead of creating an entirely new path type each time means that users no longer have to settle for a path result just because they feel they’ve invested too much time to abandon it and try something new

Controlling the Tool Contact Point

While minimizing burring is important for efficient machining, they remain inevitable in the vast majority of parts that require high-quality surface finishes. The Deburr function in Mastercam 2023 has been improved to make removing these blemishes even easier by allowing users to fix the tool contact point on the cone/cylinder option. This controls the ratio of the flute length on any supported ball, taper, or endmill tool that comes into contact with the stock material.

And now, more tools than ever are supported. There’s no need to waste time finding the perfect tool to fit the project; most shops will already have an assortment of tools that they can use with Deburr. Users can now achieve larger chamfers, use a wider range of cutting tools, and mimic a Swarf toolpath with the selection of just a solid edge. Programmers can find this option on the Tool Axis Control page.

B-Axis Contour Turning Toolpath

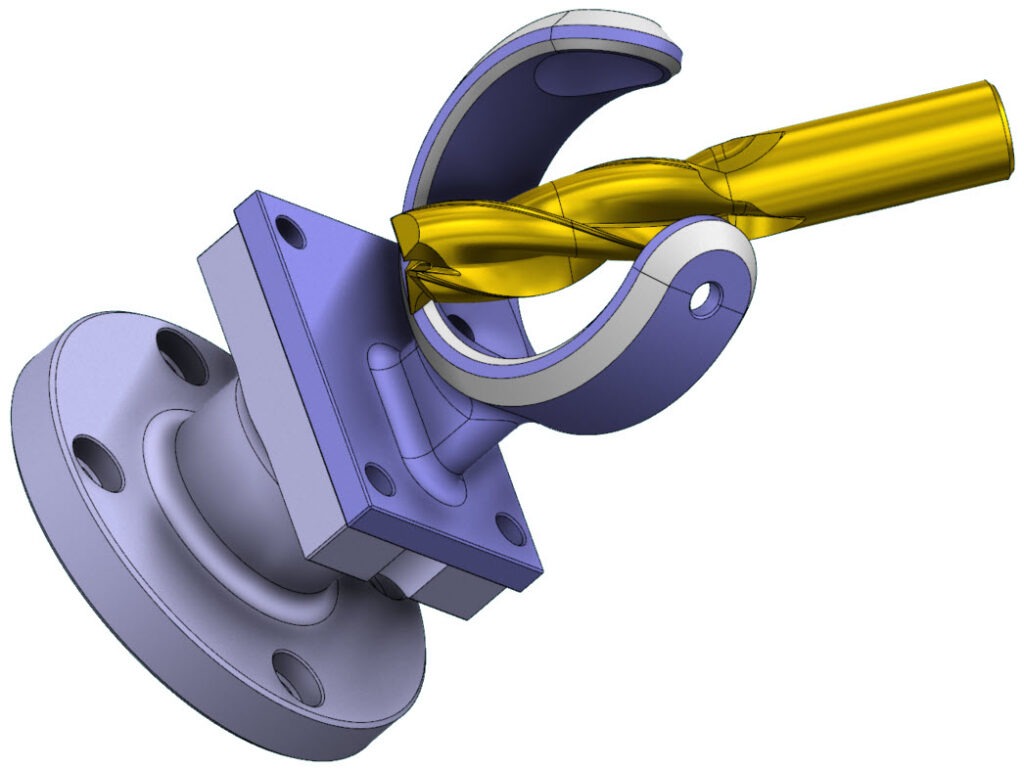

Multiaxis technology doesn’t stop with the Multiaxis product. Mastercam Mill-Turn solutions now include B-Axis Contour Turning, a finishing toolpath that borrows multiaxis motion. It allows for rotation along the B-axis as the cutting tool is engaged with the material. Users can opt to keep the toolpath motion running automatically or use manual motion control. The automatic preset offers the safest toolpath contour motion, but manual mode provides absolute control over all the contour angles being machined.

B-axis turning means that part features that traditionally required multiple operations can now be cut in a single toolpath. Long cuts in difficult-to-machine materials can benefit greatly from rotating the tool while cutting by spreading the wear over a larger portion of the insert, significantly increasing tool life.

Ready to upgrade?

Reach out to your local Reseller to learn more about Mastercam 2023 multiaxis features and get started today.