For some industries, zero liquid discharge (ZLD) has been in place for many years, but companies in consumer packaged goods (CPG) industries face unique technical and commercial hurdles to water reuse. This article looks at the food and beverage (F&B) industry as a case study for what companies are doing to achieve ZLD and what the future of ZLD will look like.

With increasing volatility in climate cycles and overuse of water sources in many areas, all major F&B companies have acknowledged the importance of water to their business. Water stewardship has evolved from meeting regulations to a business and operations priority. According to Barclay’s Data Science team, mentions of water during earnings calls increased 43% in the second quarter of 2020, compared to the end of 2019.1

The F&B industry is the third most water-intensive sector in the U.S. — following chemical processing and refining. As large consumers of water, F&B processors are also large producers of wastewater, with an estimated 1.4 billion liters of wastewater generated annually in the U.S. alone. In many cases, companies have implemented the simpler water reduction strategies and are increasingly looking to water reuse and ZLD to mitigate water supply and improve corporate water stewardship. However, there is still a long way to go before these efforts are fully realized. According to CDP, a global disclosure system for corporations to report their environmental impacts, almost two-thirds of companies are reducing or maintaining their water withdrawals, but only 4.4% of businesses are reporting progress against water pollution reduction targets.2 The adage, what gets measured gets managed, shows that wastewater management has not been top-of-mind for most companies.

Zero liquid discharge or minimal liquid discharge

ZLD is a process for recovering all (or almost all) water from wastewater that would otherwise be discharged. This water is reused on-site, and other components present in the wastewater are disposed of or recovered. When it comes to ZLD, there is no one-size-fits-all approach; each project will be different, depending on the wastewater composition, flows, costs and reuse objectives.

Wastewater treatment gets more costly and challenging as water recovery increases, meaning going from 80% to 90% recovery is harder than going from 50% to 60%. Another challenge is finding applications to use this treated water. As a result, most companies are looking to minimal liquid discharge (MLD) instead of full ZLD. MLD can still recover 70% to 90% of process water, at a lower cost and technology requirement.

Many challenges

ZLD projects in F&B companies have had limited success in North America for a variety of reasons, including technical, organizational and customer acceptance. CPG brand reputation is critical, and consumer perception of water reuse can limit recycled water applications. Other challenges include differing regulations across sites, a relatively low cost to dispose of wastewater compared to operational budget, food safety concerns, and expensive and energy-intensive technologies. For brownfield sites, there are operational challenges, such as separating streams that can impact production and increase project cost.

Start with reuse for purpose and company goals

The first step is to understand the goals for water reuse. This will drive how clean the water needs to be and, consequently, what technologies are needed. The most common applications of recycled water are for cooling and heating, cleaning, sanitation and irrigation. Local and national guidelines will dictate what level of quality the recycled water needs to be for different purposes of reuse. Recycled water needs to be, at a minimum, drinking water quality — to come into contact with anything that will touch food surfaces, such as bottle-washing or clean-in-place (CIP) systems.

The more that water is central to company goals, the more support will exist to implement ZLD projects. For example, Carlsberg Group has a commitment of zero water waste and halving its water consumption by 2030. The company recently inaugurated a wastewater treatment facility that will reuse up to 90% of process wastewater, and learnings will be adopted at its other sites globally.

Don’t use water in the first place

The best way to reduce wastewater is to reduce water usage. Companies just getting started with water reuse can conduct water mapping of the flow of water to understand where losses occur. This includes looking at the process to understand where water can be reduced or changes that could be made to make water reuse easier. It could identify improvements such as processes that can be changed (e.g., dry peeling), finding and fixing leaks, technology upgrades (e.g., putting in CIP systems instead of hoses for washdown) and increasing training and awareness of employees. Companies may need to invest in sensors or water meters to understand the true flow of water.

One challenge companies often face as they implement water reduction strategies is that once the low-hanging fruit is gone, it becomes harder and more expensive to squeeze more water from the process. Many companies have already reported a 40% to 50% reduction in water-use ratio over the past five years. Another challenge is that as conservation increases and water-use ratio declines, the wastewater becomes more concentrated and can be more difficult to treat.

Treatment choices depend on wastewater profile

There is no single ZLD or water reuse system. Each project will have different technology requirements based on the wastewater composition and company goals. Wastewater streams from F&B sites are complex and will require multiple treatment technologies to reach reuse quality. Running a water chemistry report on the effluent will help understand what systems are needed. Typical constituents in F&B wastewater include:

- Biochemical oxygen demand (BOD) is a measure of the amount of biologically degradable organic content (typically sugar) that exists in a wastewater stream. BOD levels will vary depending on several factors, including the type of product (e.g., it will be much higher for a sugar factory than brewery) and whether the high-strength streams are separated out.

- Total suspended solids (TSS) is a measure of the concentration of solids in the wastewater.

- Fats, oils and grease (FOG).

- Total dissolved solids (TDS) is a measure of dissolved solids (typically salts). This could be high if the facility has brining operations and is common from washdowns/pH adjustment.

- Nitrogen and phosphorus — nutrients that result in algae blooms downstream.

- Lubricants — from washing conveyors and equipment.

- Solvents or cleaning agents.

Depending on the effluent profile and treatment goals, a F&B company likely will use a range of coagulation, separation or filtration (to remove solids, lubricants and even pathogens), aerobic or anaerobic biological treatment (to remove BOD and TSS), and reverse osmosis (to remove TDS and other remaining constituents).

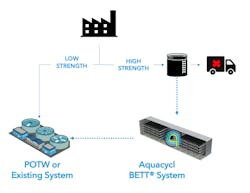

Over the past five years, substantial innovation has taken place in the water and wastewater treatment market, and as new technologies emerge, companies have more options available for industrial treatment. For example, companies that have very high BOD wastewater, such as from discarded product, were limited by traditional technology. The only option was to truck or dilute the concentrated wastewater. Aquacycl’s BETT system, for example, provides a more efficient way to treat the high-BOD wastewater. By separating and concentrating small volumes of high-strength streams, companies can treat the remaining high-volume/low-concentration wastewater with less infrastructure and less energy to achieve ZLD or MLD.

Is ZLD realistic and achievable?

ZLD rightly receives a lot of attention, and the industry has clearly recognized the importance of reducing and reusing water wherever possible to improve sustainability, mitigate business risks and reduce future costs. However, even when the economics make sense, companies may not have applications for complete reuse of process wastewater. For example, if a company is able to recycle 55% to 65% of its wastewater, after using the recycled water in cooling towers, irrigation and non-process applications, they are still left with about 25% excess water that has nowhere to go.

If manufacturing sites are located within an industrial park or near agricultural operation, this could be a solution for the excess water, but these are largely outside the control of the manufacturer. One example of this is South African Breweries (SAB), which recently announced a project to use brewery wastewater to grow spinach, and aptly named it “Project Popeye.” The nutrients present in the wastewater become fertilizer for the spinach and as the water is cleaned, it becomes available for reuse in the brewery.

Similarly, there are examples of industrial parks where multiple companies share services, such as water, heat and other outputs of their various processes. Excess water from F&B companies may be acceptable quality for water needed in other industries.

So, is ZLD realistic and achievable? The answer, as with most questions in wastewater management, is “it depends.” It depends on the profile of the wastewater, company appetite, local infrastructure and regulations, and the amount of water available for reuse. Reusing water as an ingredient in the product, while technically feasible, is still far from accepted, and F&B companies are not willing to put their brand reputation at stake. Implementing new technologies that enable water reuse will help, but, at least for the near term, minimal liquid discharge is a more realistic goal for most F&B companies.

References

2. https://www.cdp.net/en/research/global-reports/global-water-report-2020.

Orianna Bretschger is the CEO and co-founder of Aquacycl, a wastewater technology company commercializing modular, plug-and-play systems for industrial wastewater based on microbial fuel cell technology.