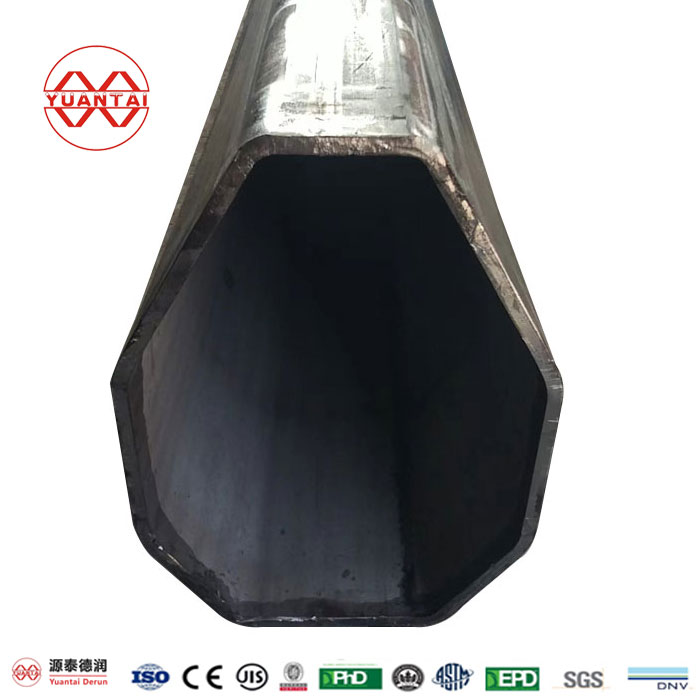

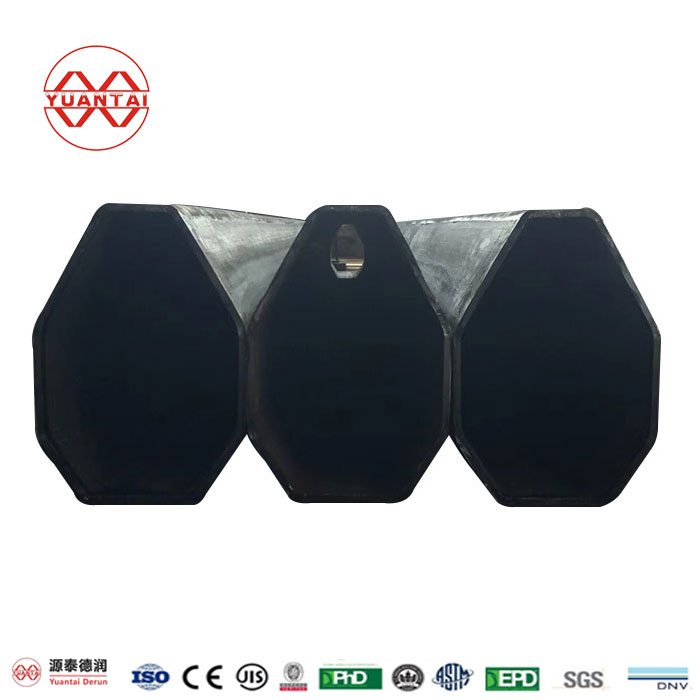

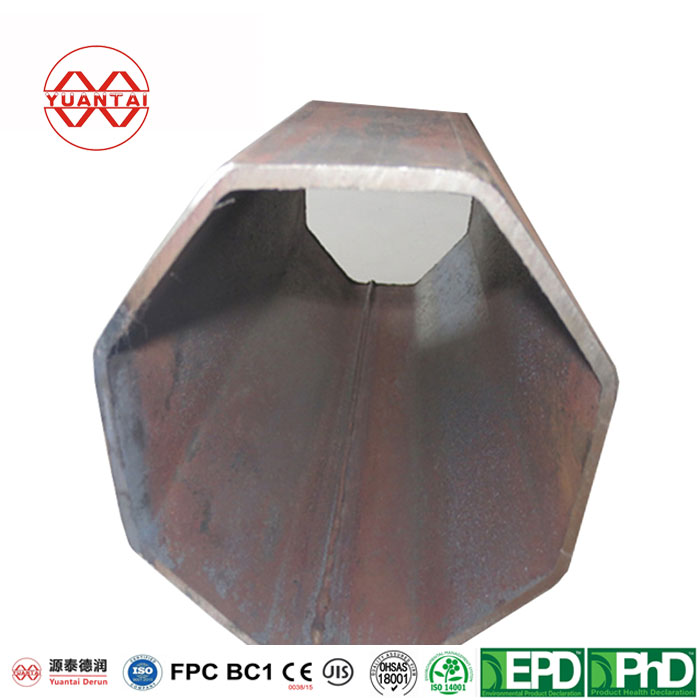

Octagonal Steel Pipe

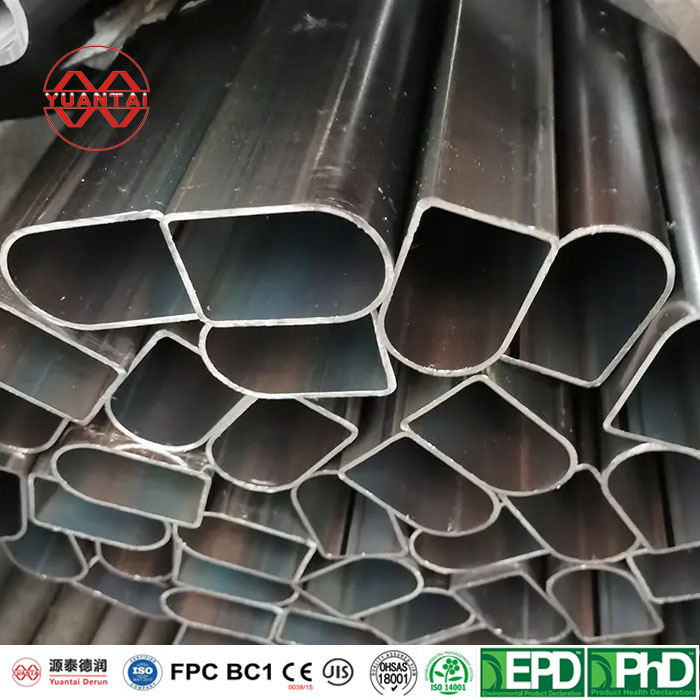

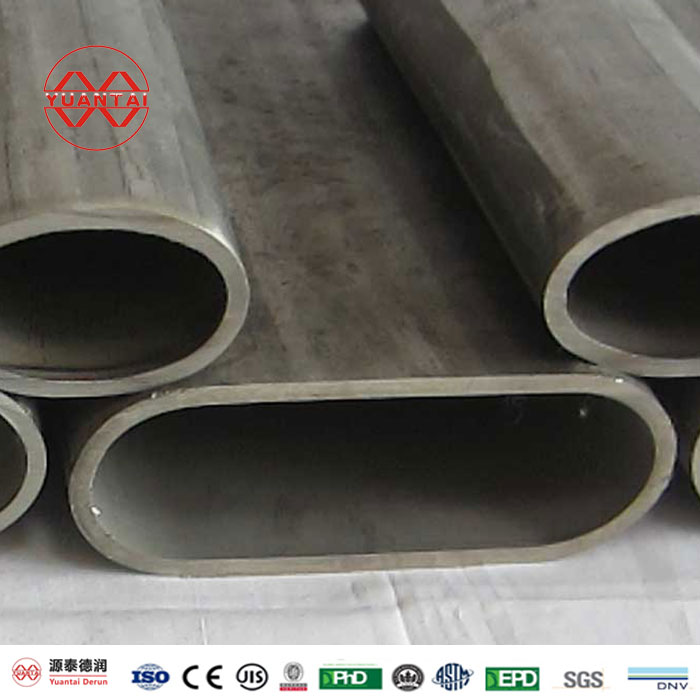

Tianjin Yuantai Derun Group has 18 wholly-owned subsidiaries, of which Tianjin Yuantai Technology Development Co., Ltd. was founded in 2014 to produce super large diameter, super thick wall square and rectangular tubes that are rare in the market. This kind of non-standard pipe is made of LSAW pipe or seamless steel pipe as raw material, which is extruded into square and rectangular pipe meeting the quality requirements. Moreover, Tianjin Yuantai Technology Development Co., Ltd. can also produce various specifications of special-shaped tubes such as right angle tubes, octagonal tubes, trapezoidal tubes, and undertake tempering and annealing processes. With the support of professional technicians and equipment, our next goal is to develop straight out special-shaped tubes.

Production specifications and technical standards

Tianjin Yuantai Science and Technology Development Co., Ltd. has 4 production units and more than 50 employees. It undertakes large-diameter thick walled square and rectangular tubes, seamless square and rectangular tubes, special specifications square and rectangular tubes, special-shaped tubes, hot rolled rectangular tubes, square tubes with specifications of 80 * 80mm-1200 * 1200mm, rectangular tubes with specifications of 50 * 100mm – 1200 * 1500mm, and wall thickness of 2.75mm-50 mm, in accordance with GB/T3091-2015, Any specifications and materials in this range (such as Q235/Q355/Q390/Q420/Q460/high-strength steel/weathering steel, etc.) can be customized. The outgoing process of hot-rolled right angle tubes is particularly advanced. Two technical methods, namely, online hot rolling of four corners and integral heating, are adopted, which has the advantages of both power saving and high efficiency.

TECHNOLOGICAL PROCESS

Inspection of round pipe (raw material) – feeding – hydraulic propulsion – roll dynamic extrusion forming (round to square) – inspection of steel pipe (overall dimension, flatness, perpendicularity, R angle) – blanking (inspection of straightness and twist of steel pipe) – mouth end shaping (there will be deformation area at the head end during deformation of steel pipe) – sawing and trimming – inspection and marking – warehousing

PROCESSING BUSINESS

The new intelligent tempering furnace equipment of Tianjin Yuantai Derun Group is mainly used to remove the internal stress inside the steel pipe. The methods of removing internal stress include natural aging and artificial aging. The natural aging is to place the steel pipe in the open field for more than half a year so that it can slowly take shape, thus eliminating or reducing the residual stress. There are two methods of artificial aging:

① Heat treatment to remove internal stress: heat the steel pipe to 550~650 ℃ for stress relief annealing, which saves time compared with natural aging and removes residual stress more thoroughly

② Vibration stress relief: in short, it is to eliminate the stress of steel pipe by vibration. Vibration aging is to use the resonance of the workpiece to apply additional alternating stress or deformation to the workpiece. When the additional alternating stress and residual stress are superposed, and the energy is absorbed through the friction inside the material, reaching or exceeding a certain threshold value of the material, the workpiece will undergo micro or macro viscoelastic plastic mechanical changes, thus reducing and homogenizing the residual stress inside the workpiece, and making its dimensional accuracy stable.

The square and rectangular tubes after annealing treatment to remove the internal stress have more guaranteed the mechanical properties, especially in yield strength, tensile strength, elongation and impact compression resistance, achieving the effect of 1+1>2.

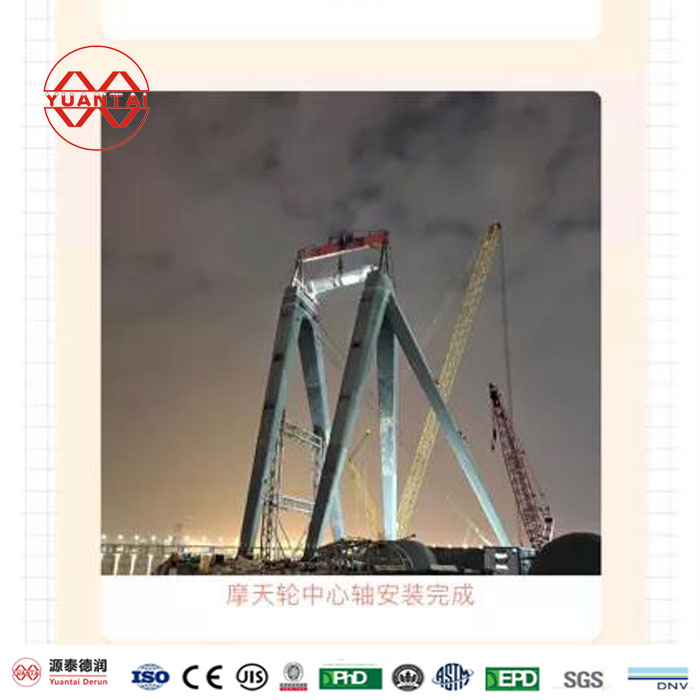

Project performance

1.The main column of the 128 meter Ferris wheel in Shenzhen Overseas Chinese Town adopts the oblique octagonal tube produced by Yuantai Technology

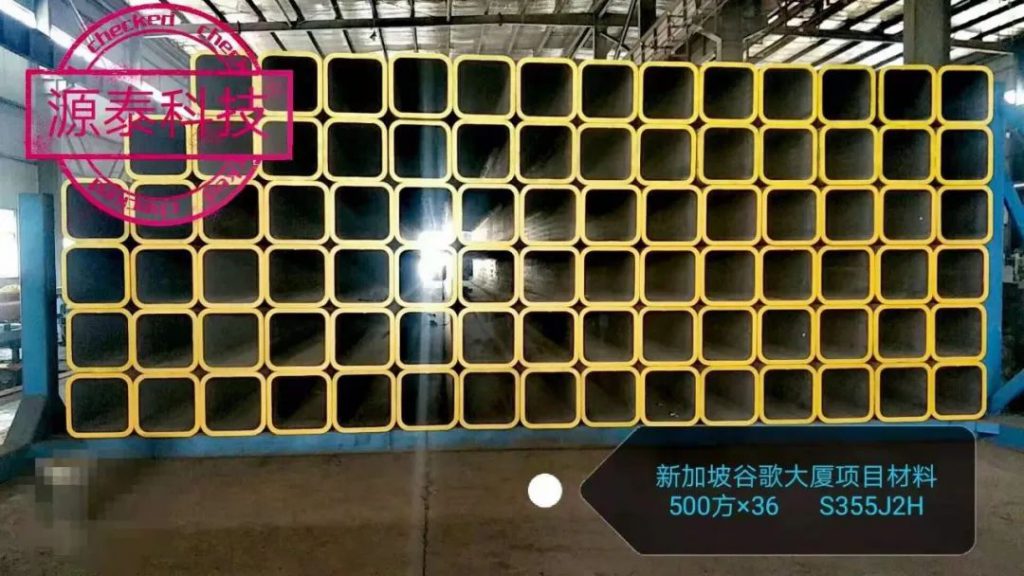

2.The Google Tower in Singapore was built with 500mm * 500mm * 36mm modified pipe produced by Yuantai Technology, S355J2H material, 4000 tons in total.

3.The establishment of Sichuan Tianfu Airport adopts 90mm * 250mm * 20mm pipes produced by Yuantai Technology

4.The establishment of the headquarters of Beijing Chaoyang Asian Investment Bank adopts the 500mm * 520mm * 22mm modified pipe produced by Yuantai Technology

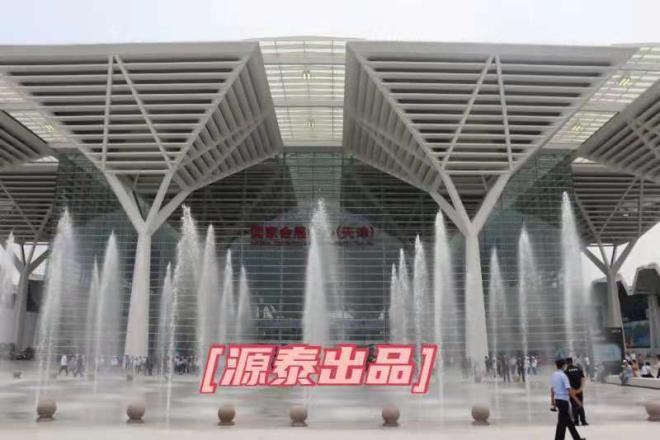

5. National Convention and Exhibition Center (Tianjin) Venues

At the first exhibition of the National Convention and Exhibition Center (Tianjin) “China Building Science Conference and Green Smart Building Expo” held on June 24, 2021, Tianjin Yuantai Derun Group provided square tube (200 × 700 × 8mm,200 × 700 × 10mm,200 × 700 × 12mm,200 × 700 × 16mm,200 × 800 × 8mm,200 × 800 × 10mm,200 × 800 × 12mm,200 × 800 × 16mm) is mainly used for column structure and supporting structure. The umbrella shaped steel structure of the main body of the entrance hall of the exhibition hall, which is the most amazing, is made of structural steel pipe products of “Yuantai Derun” brand.

It is well known that square tube is a kind of light thin-walled steel tube with hollow square section, also known as steel cold-formed sections. In addition to wall thickness thickening, the size of corners and straightness of edges of hot-rolled extra thick wall square tubes have reached or even exceeded the level of resistance welded cold-formed square tubes. Tianjin Yuantai Derun Group welcomes customers to actively consult various orders for special-shaped tubes and challenge various impossibilities!